- 首頁

- 關(guān)于我們

- 新聞中心

- 公司業(yè)務(wù)

- 工程業(yè)績

- 聯(lián)系我們

- 國家法規(guī)

-

全國統(tǒng)一服務(wù)熱線400-117-5858

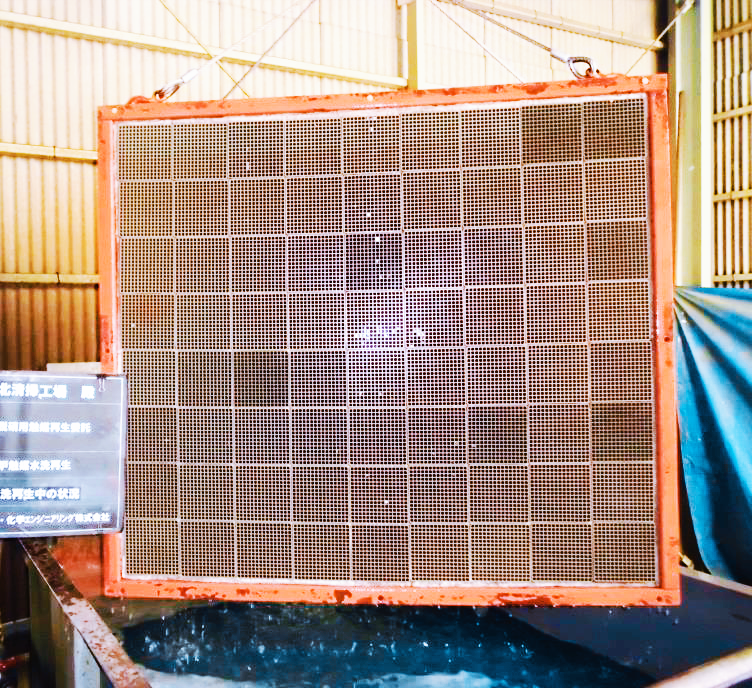

催化劑模塊尺寸:1839x925x1230

最高承受溫度:420℃

Corrugated plate catalyst

Maximum temperature: 420 ℃

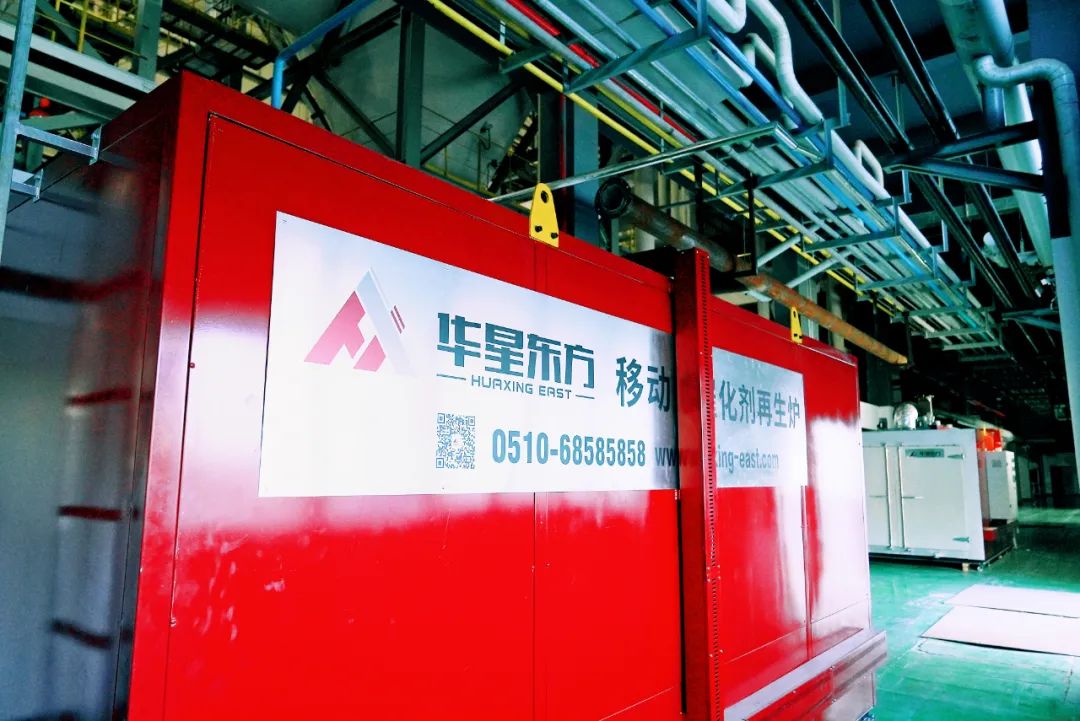

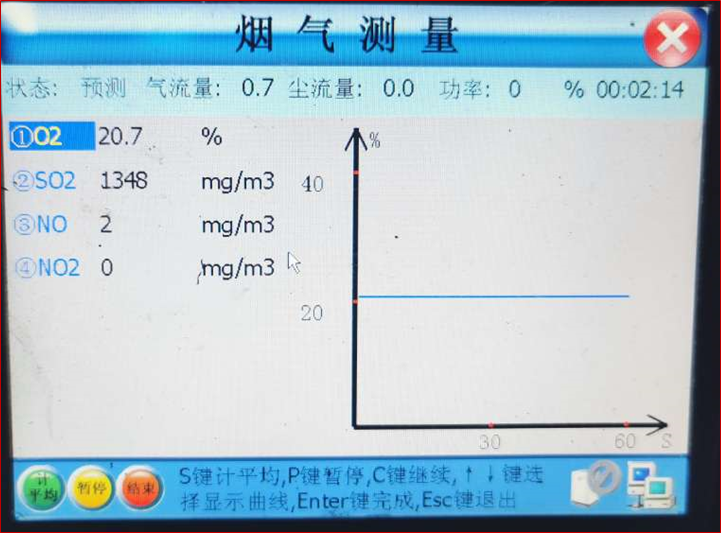

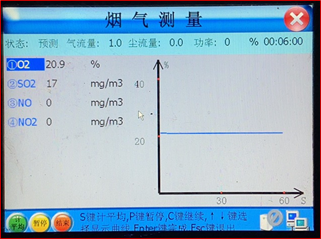

In 2016, Huaxing reached a technology transfer agreement with Mitsubishi Heavy Industries (MHI) of Japan, which authorized the transfer of advanced ultra-clean emission technology of flue gas cleaning (FGC) to Huaxing. As a leading company in the field of waste incineration in the world, MHI owns advanced FGC technologies, such as single-tower dual-cycle wet scrubbing, low-temperature flue gas denitration, catalyst offline regeneration, as well as relevant engineering experiences. Huaxing has successively introduced the production and manufacturing technology of MHI's wet scrubbing, low-temperature SCR denitration, third-generation low-temperature denitration catalyst ( Exclusive license in China ), and catalyst offline regeneration ( Exclusive license in China ). These technologies are mainly applicable to flue gas generated by municipal waste, hazardous waste, and sludge incineration.